2.9 inch Digital Price Tag E-ink Electronic Shelf Label With Buttons for Warehousing

- Model

- SETW0290B

Item specifics

- Display Size

- 2.9 inch

- Dimension

- 45.1 * 107.9 * 16

- Weight

- 89g

- Color Display

- Black and White

- Screen Resolution

- 296 × 128

- Communication Band

- 433MHz

- Response Time

- 3S(Configurable)

- Battery Life

- Not less than 2 years,Replaceable

- Battery

- CR2450*2

Review

Description

2.9 inch Digital Price Tag E-ink Electronic Shelf Label with Two Buttons for Warehousing

Feature

1. Low energy

2. Black and white

3. Cloud or local Server based options

4. 433MHz/868 MHz /915 MHz communication

5. 296*128pixels full graphic, E-Paper displays

6. Perfect for the retails, warehouses, logistics management and meeting system

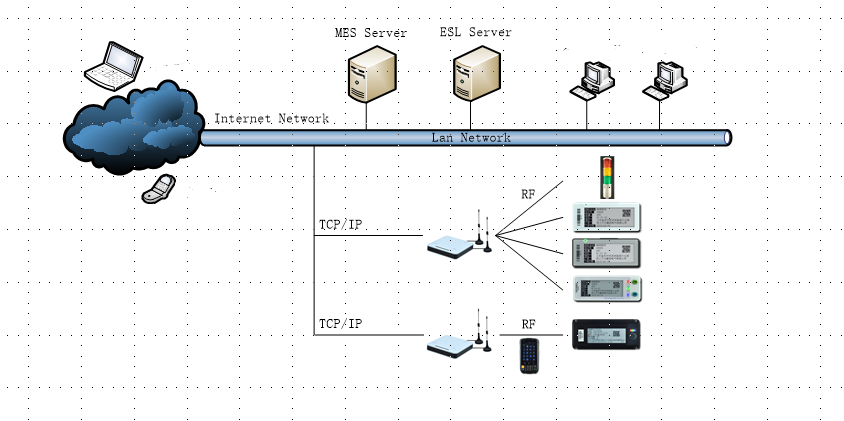

System Architecture

Solution for Intelligent warehousing

Why Choose Sertag's Electronic Shelf Labels?

Using advanced electronic shelf labels and ultra-low power consumption wireless networking technology, the operation information generated in the process of warehousing, goods picking, stock taking and other processes is realized, and the real-time interaction with MES system is realized.

Realize informatization, paperless management and fine management of goods and storage space;

Label system and management system docking, analysis of inventory status, real-time storage management;

MES system confirms task list and automatically assigns tasks to operators;

To realize the segmentation and merging of documents to satisfy the simultaneous operation of multiple orders and multiple people;

Design batch management and efficiency management during picking and allocation, and realize fifo control of materials;And can achieve the designated materials for priority distribution;

All business documents are automatically extracted from MES system to realize real-time synchronization of warehouse electronic label system and MES data.Create an independent database to record the information that cannot be recorded by ERP at present as the supplement and improvement of ERP;

Provide a variety of query conditions, to solve the operator experience management bottleneck, to avoid staff mobility caused by the loss of the enterprise;

System operation is simple and clear, easy to learn and easy to understand, make full use of the information resources, reduce the workload of information input, reduce the labor intensity of operators.

Application